Value vs Non-Value Added Activities

June 10th, 2018

I wrote a (short) autobiography when I was in 5th grade. My concluding sentence was:

“It’s better to be busy than to be bored—to live a full life than an empty one.”

I’m not sure if I agree with 10-year-old Kevin. Depending on the process, I’d gladly cut certain activities in exchange for the boredom.

Any process can be thought of as performing activities with inputs in order to produce outputs.

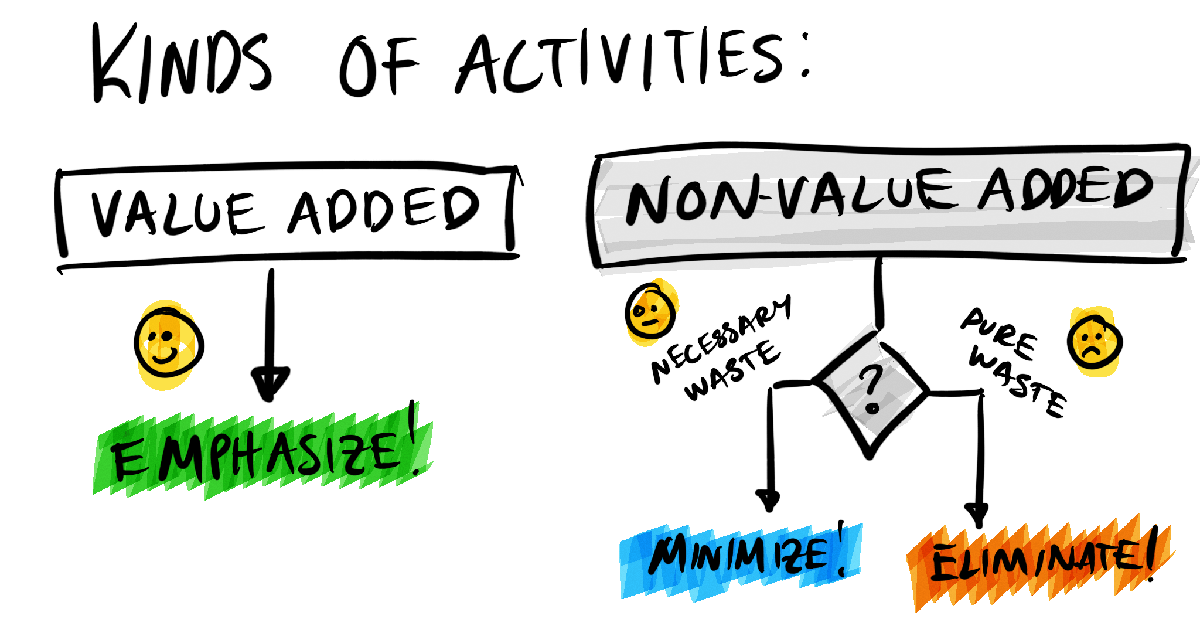

We hopefully create value through those activities. And Lean Thinking distinguishes which activities are “value added” versus “non-value added.”

If we’re making a pizza, sprinkling delicious cheese is value-added. Letting the oven pre-heat might be non-value added, but “necessary waste.” However, waiting for the oven to free up or fixing a botched sauce are non-value-added activities — “pure waste.”

We should aim to emphasize value-added activities, minimize necessary waste, and eliminate pure waste.

That said, classifying activities can be easier said than done. First, value must be clearly defined (Value = delicious pizza? What does delicious mean? For whom?). Second, categorization should go beyond intuition. Use data. Observe the process. Gather perspectives.

Mm… Pizza. 🍕